Other automation equipment

Other automation equipment

PXT-1220:Payload:20kg; Processing capacity:8 boxes/min

PXT-1235: Payload:35kg; Processing capacity:10 boxes/min

PXL-1535: Payload:35kg; Processing capacity:10 boxes/min

PXW-1420: Payload:20kg; Processing capacity:10 boxes/min

PXW-1535: Payload:35kg; Processing capacity:10 boxes/min

PXW-1550: Payload:50kg; Processing capacity:10 boxes/min

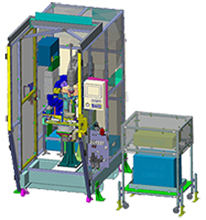

● High speed and high precision: the fastest forward speed can reach 2.8 m/s.

● Small and flexible: it is nearly 1 times shorter than the size of 1st slide arm, and can achieve free and accurate rotation of the fixture from 0° to 300°.

● Suitable for various robot manufacturers.

● The motor and control system can control the traverse axis by using the robot's additional axis function (additional option).

● It is able to coordinate movements so that posture and speed can be synchronized , and the movement is smooth.

●Flexible tooling, Quick changeover (within 5s) 。

Suitable for a variety of post-processing needs 。

● At the customer's plant, 20 different products have been processed in one machine 。

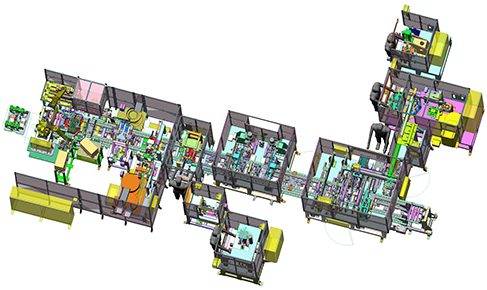

● Fully automatic assembly line, the cycle time is 6.5s or less 。

● A variety of assembly - oiling - press fitting - laser welding – QA - automatic boxing of fully automated equipment 。

● Electromagnetically induced heating to complete the heating of parts instantly 。

● The tooling can be replaced, corresponding to multi-variety production 。

● Long and short slide rails (up to 2M), electric and manual, rich achievements 。

● Flexible upper and lower rail combination equipment, multi-variety correspondence, oiled running in force measurement one integrated correspondence 。

● A variety of assembly - oiling - running-in - press-fitting - electric gun tightening - QA - automatic labeling - laser coding and other multi-engineering correspondence。

● Electronic Kanban, important performance traceability of line body, production management system, CPK statistics, etc 。